superior line

Versatility, durability, and functional design

The Fortec Door from the Superior line is the ideal choice for those seeking a reliable, aesthetic, and accessible solution for their interior spaces. Its drum-shaped design, featuring UV-coated HDF faces and a semi-gloss finish, gives it a modern appearance that is resistant to daily use.

With a honeycomb core and a solid wood perimeter frame, this door guarantees a lightweight yet stable structure. Its overall thickness of 36 mm provides strength and support, and it features internal reinforcement for a lock, making it ideal for homes, offices, and institutional settings.

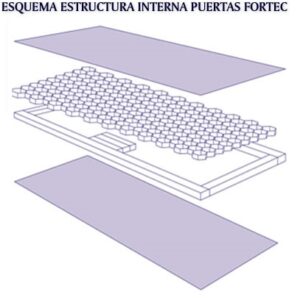

Structure

The hollow-core door from Fortec’s Superior Line is built, as shown in its structure, with two 3 mm standard HDF panels painted and protected with UV varnish (wood fiberboard), featuring a semi-gloss finish. For the internal filling, we use Honeycomb, a 30 mm perimeter wooden frame, and a reinforced section on one side with solid wood for the lock, resulting in a final thickness of 36 mm. Fortec is the commercial brand for doors manufactured by Madeflex S.A.

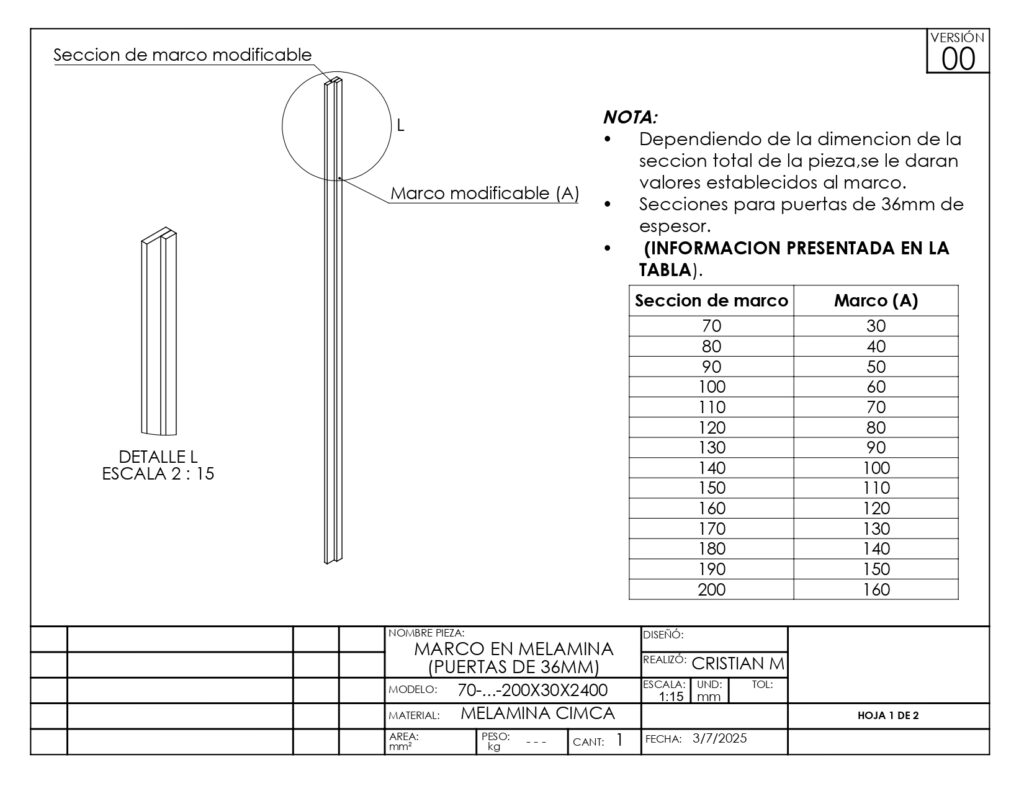

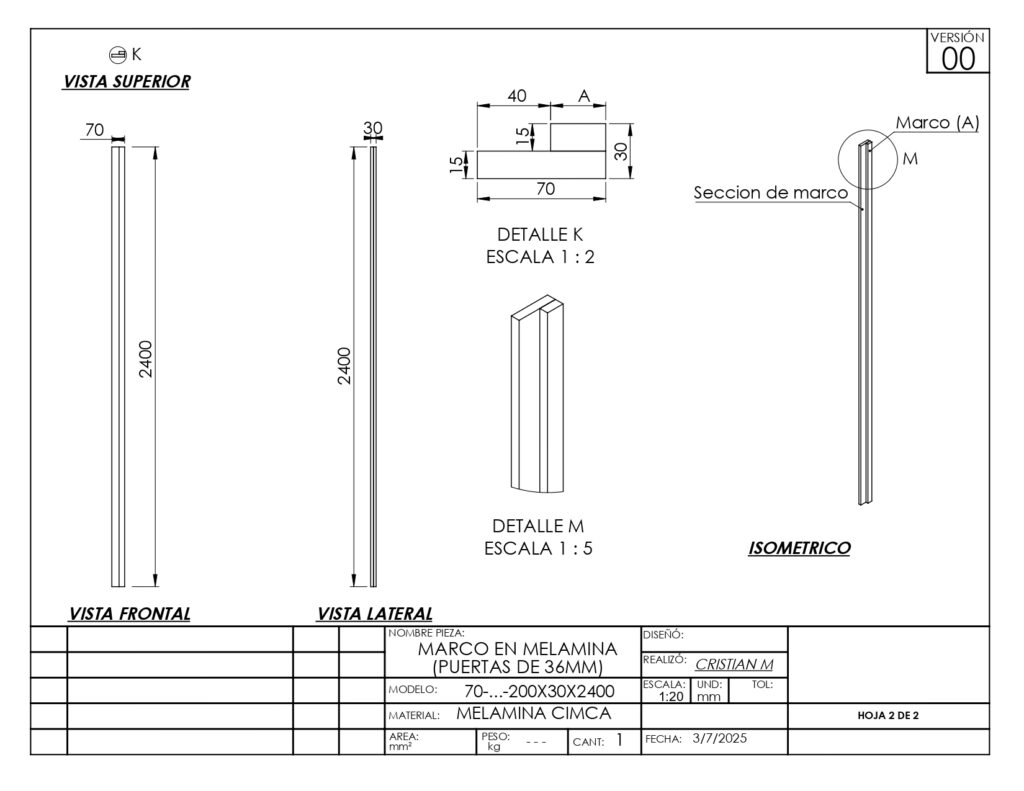

Frame

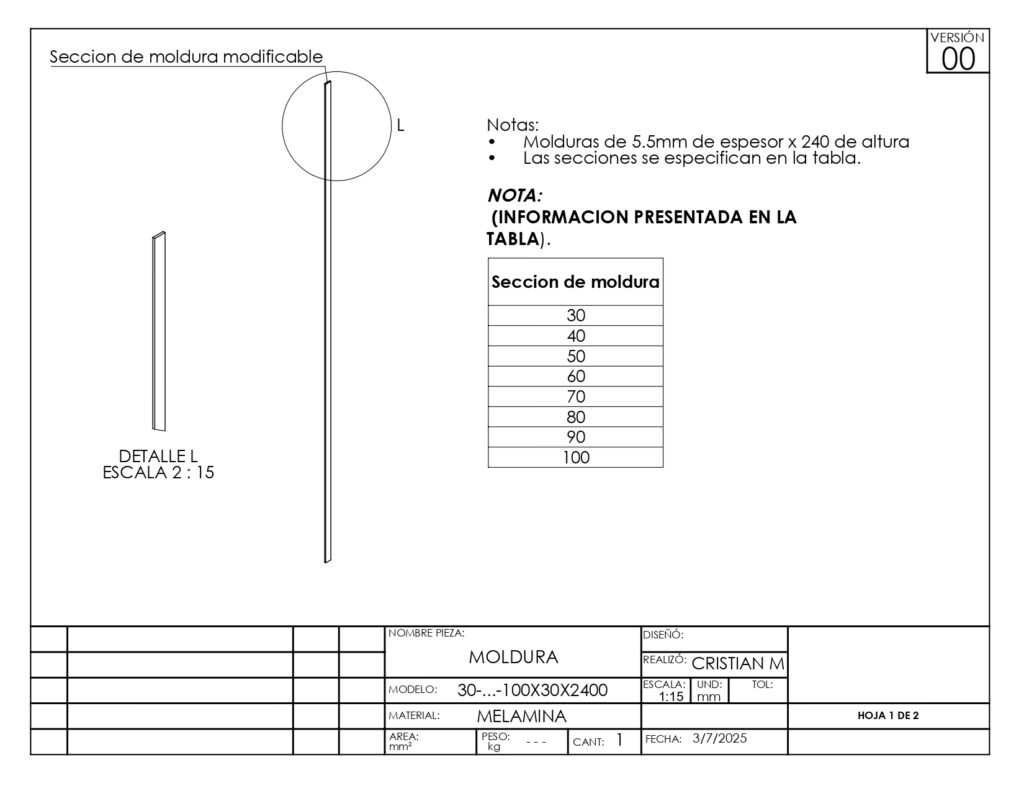

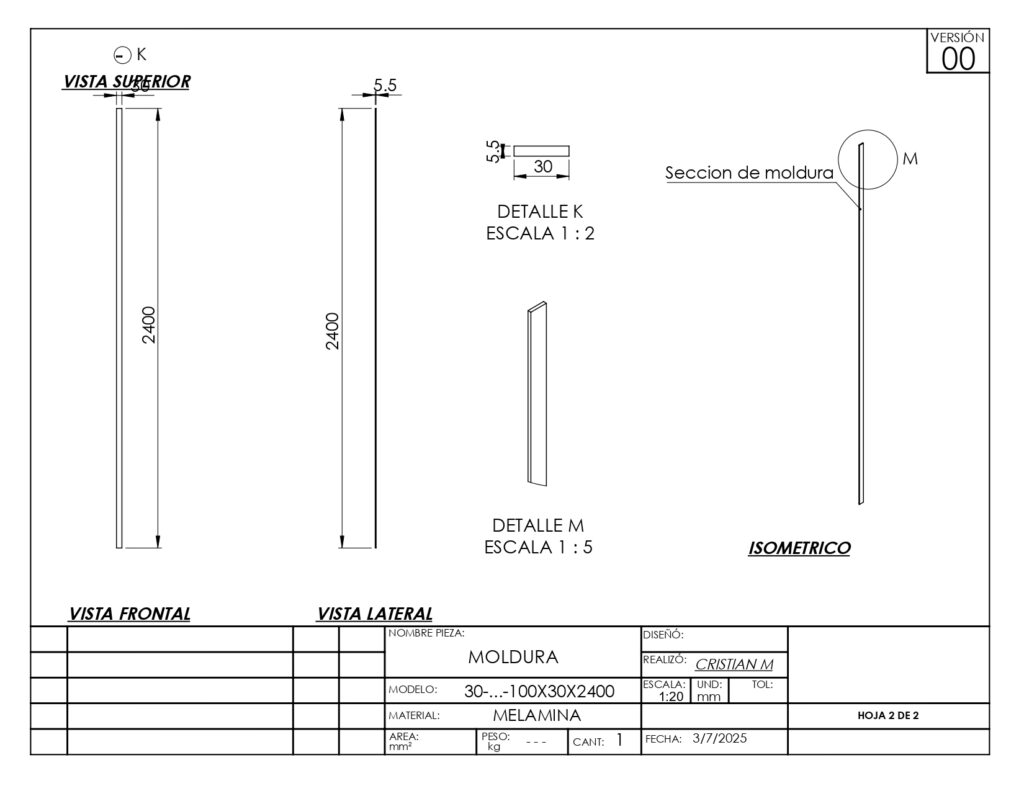

Molding

Hinges

Induma’s Omega hinge is a versatile and efficient solution, suitable for a variety of environments: from residential furniture to office doors or light construction projects. With multiple finishes that combine style and strength, they offer good durability, easy installation, and a polished aesthetic. Perfect if you’re looking for a solid, affordable, and domestically manufactured hinge.

Durability

The durability of a door is closely linked to its proper or improper use. Predicting its useful life is difficult given the countless variables involved, including installation method, environmental factors, maintenance, and more.

Use

Fortec hollow-core doors should not be exposed to water or excessive humidity. They should be cleaned with a dry or slightly damp cloth, without detergents or solvents. They must not be subjected to strong impacts caused by wind or heavy objects, and sharp objects should not be dragged across their surface.

sobre su superficie.

Planing and beveling

The allowable tolerance for making cuts is 5 mm on each side; otherwise, the door’s unique strength characteristics will be lost. It’s important to note that it’s recommended to make the cut on the side where the lock will be installed to prevent the door from sagging. When planing the door, it’s important to use a sharp tool (plane or router), chamfer again to prevent the edges from deteriorating, and paint the edges.

When cutting the door, it is necessary to immunize its frame, otherwise it is exposed to termite attack.

Tolerances in measurements

According to the Colombian Technical Standard NTC 2569, the length and width dimensions may have a tolerance of 2.5 mm on the dimension agreed between the buyer and producer and 1 mm on the thickness.

Lock plug

Our doors have an internal locking pin on one side only. This pin is made of wood and measures 40 cm long x 9 cm wide. It is located exactly in the center of the door for doors up to 2.10 m high. If the door exceeds this limit, the height of the pin must be specified to the Sales Representative. To determine which side the pin is located on, check the two horizontal frames (headers). At the end, you will find a low-relief X.

Storage

Fortec doors should be stored horizontally in stacks of up to 50 units on flat, smooth surfaces. They should be stored in a dry, clean location protected from water and sunlight.

Packing

These doors are packaged with expandable plastic to protect them from scratches and dirt, and painted and laminated doors are fitted with corrugated cardboard at all ends. It is recommended that if the door is unpacked and not used immediately, it should be repackaged in the same plastic to avoid the aforementioned inconveniences. It is important to keep in mind that when unloading a door, one should not slide over the other to avoid scratches.

Reception

All received doors must be inspected in front of the driver so that any broken or scratched items can be returned immediately, and a note indicating any defects can be placed on the invoice.

Installation

The recommendation is to carry out a good installation, ensuring the frame is parallel to the door, good quality hardware in adequate numbers, and keeping expansions and tolerances within standard limits.